After only a few hours of use, things were not looking too bright for the Fanatec CSL base and steering wheel with QR1. A quick Google and I see posts describing a couple mm gap at the collar, could be the issue.

Another quick, “a-ha” addressing the “runout” gap, and continued to enjoy the wheel… But this was short lived and every few hours of use the issue would repeat.

Thinking about this, it occurred to me that this friction based fitting had one fundamental flaw which might be easy to address. The contact surfaces are too smooth and slippery. I believe there’s a technical term to measure this called the coefficient of friction.

To make the contact surfaces less slippery and have more grip, we can do two things: make them rougher; and remove anything they might lubricate (e.g. skin oils, dirt, dust, etc).

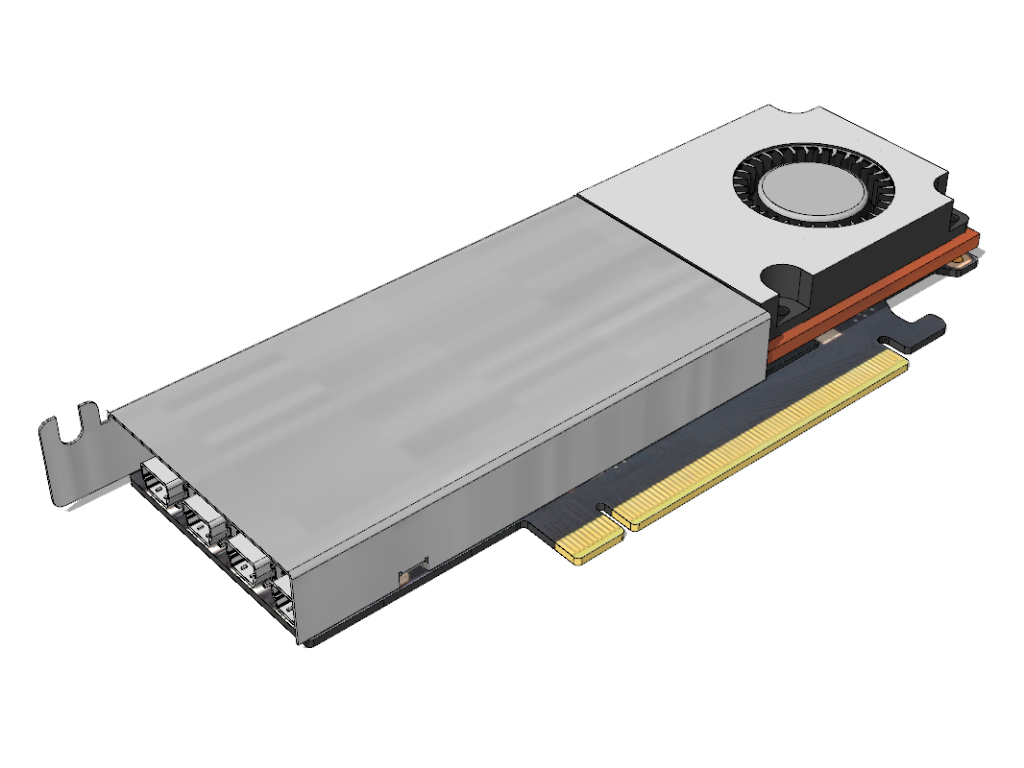

As the pictures show, I roughed up the inner plastic contact surfaces. You can see the plastic surfaces will apply pressure from above and below only, not the sides, so the emphasis for the painted metal surfaces of the QR1 shaft was focused on these areas.

Then a good clean with alcohol to eliminate any dust, dirt and oils and we have a much less slippery surface.

Two weeks later and no issues. Design appears to be better with this simple and quick modification.

Leave a comment